DSG Mechatronics Repair Austria

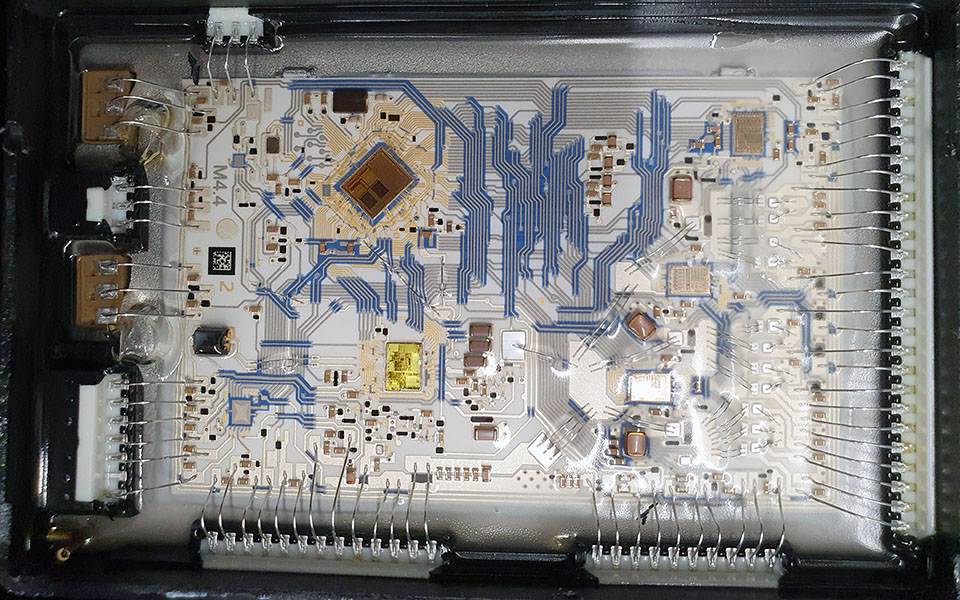

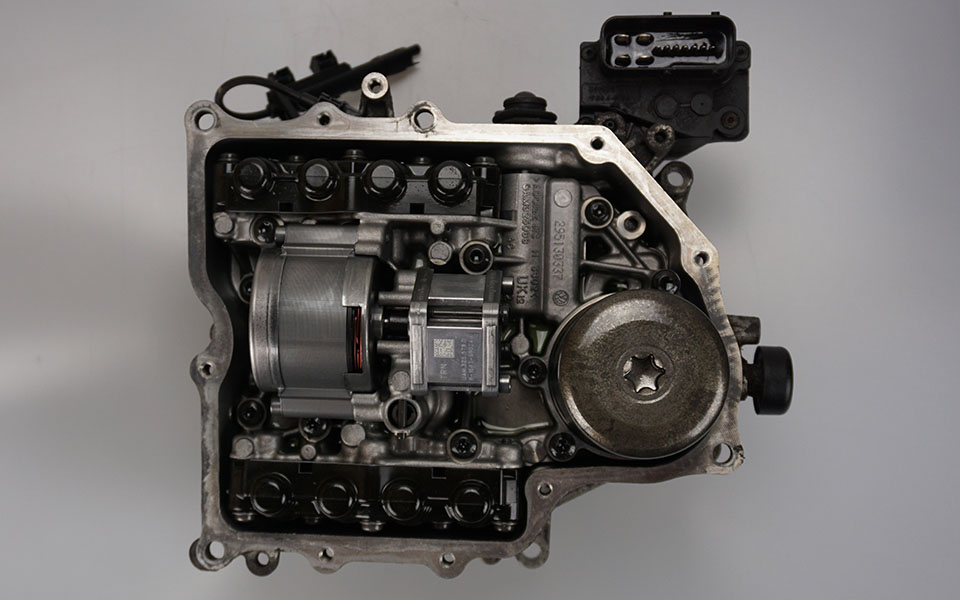

We offer fast DSG mechatronic repairs in Austria. One of the most common problems with the DSG7 (DQ200) at present is the pressure loss error caused by cracks in the die-cast aluminium housing or a defective sealing ring. As a result, the transmission control unit can no longer build up and maintain the required pressure. However, various typical defects also occur in the DQ381, which we repair professionally. You can find more information on how the DSG works in the Wikipedia article Dual clutch transmission. Also for our professional Control unit repair and for the first Speedometer repair from Austria we have written interesting articles.

Repair kit for DSG mechatronics repair

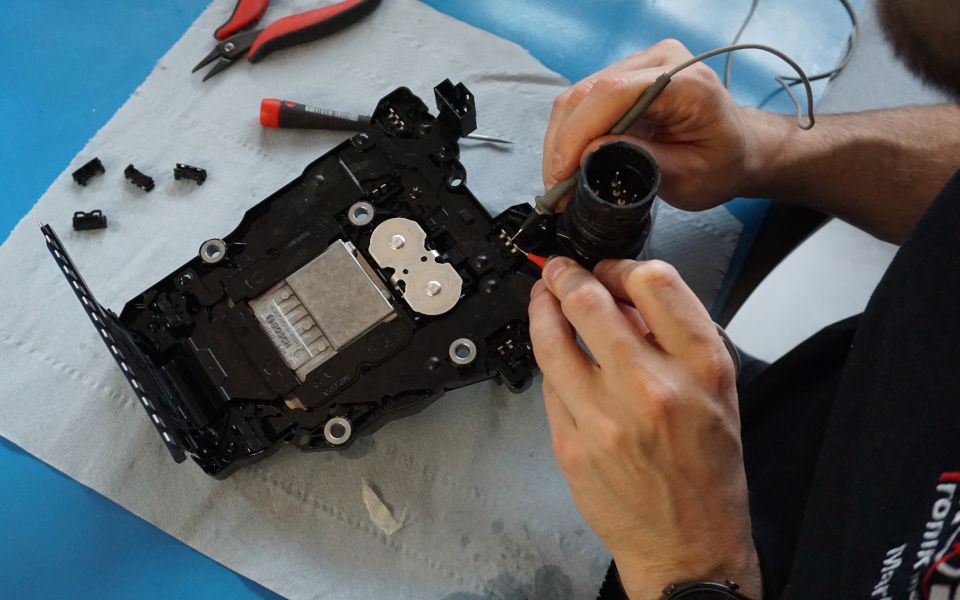

With the repair kit for the DSG7 or DQ200, the pressure loss fault can be rectified. For the DSG mechatronic repair to be successful, the original pressure accumulator must be removed and a stainless steel insert inserted. Now the new pressure accumulator can be screwed into the insert. By using the insert, it does not matter if the aluminium housing is cracked.

Error codes and problems of the DSG7 mechatronics

The loss of pressure in the DSG7 mechatronics naturally causes various symptoms in the vehicle. Among other things, the gearshift indicator ("PRNDS") may flash, the gearbox may no longer shift correctly, or the fuse for the gearbox control unit may blow. Various error codes are also stored. Repair is possible for the following error codes.

| Error code | VAG code | Error description according to tester |

|---|---|---|

| P0562 | 16946 | System voltage error, voltage too low |

| P0841 | 17255 | Hydraulic oil pressure sensor |

| P1604 | 18012 | Control unit error |

| P177F | – | Hydraulic pump system, overload protection |

| P17BF | – | Function restriction, pressure drop |

| P1895 | 18303 | Functional limitation, lack of pressure |

| P189C | 006300 | Functional restriction, low pressure build-up |

Other fault codes for DSG7 or DQ200

Contamination by metal particles can lead to other error entries. First check the position sensors and magnets for contamination. If you notice any unusual contamination, the DSG must be checked for mechanical damage and wear. If you do not find anything, clean the sensors and check whether the error code is still present. If this does not help, it can be assumed that the pressure accumulator is damaged. This applies to the following error codes.

| Error code | Error description according to tester |

|---|---|

| P173A | Position sensor 1 for gear selector, improbable signal |

| P173B | Position sensor 2 for gear selector, improbable signal |

| P173C | Position sensor 3 for gear selector, improbable signal |

| P173D | Position sensor 4 for gear selector, improbable signal |

Installation-related error codes

After the DSG mechatronic repair and installation, the following error codes sometimes appear. These occur when one or more shift bolts are not correctly fitted in the gearbox shift forks. When installing the mechatronics, make sure that all bolts are correctly fitted.

| Error code | Error description according to tester |

|---|---|

| P072A | Gearbox stuck in neutral |

| P072B | Gearbox stuck in reverse gear |

| P072C | Gearbox stuck in 1st gear |

| P072D | Gearbox stuck in 2nd gear |

| P072E | Gearbox stuck in 3rd gear |

| P072F | Gearbox stuck in 4th gear |

| P073A | Gearbox stuck in 5th gear |

| P073B | Gearbox stuck in 6th gear |

| P073C | Gearbox stuck in 7th gear |

DQ381 (0GC) Repair

The DQ381 (0GC) transmission control unit is a modern 7-speed dual-clutch gearbox (DSG) that is installed in many VW, Audi, Seat and Škoda models. As with many electronically controlled gearboxes, defects can occur over time, making a DQ381 (0GC) repair necessary. Problems can manifest themselves in jerky gear changes, delayed reactions or sudden switching to emergency mode. Early diagnosis and repair can prevent expensive consequential damage and significantly extend the service life of the transmission.

Common errors with DQ381

Typical problems with the DQ381 (0GC) include the pressure sensors and the clutch control unit. Error codes frequently occur which indicate implausible sensor values or a faulty transmission control unit. The following error codes are read from the transmission control unit using the tester:

- P0805 - Clutch position sensor function faulty

- P1735 (10666) - Clutch 1 position sensor, electrical error

- P1736 (10668) - Clutch 2 position sensor, electrical error

These errors indicate a defect in the position sensors of the clutches, which can lead to shifting problems or an emergency stop. In this case, only the defective position sensor is replaced to rectify the problem. A targeted diagnosis and repair can help to restore the transmission to perfect condition and avoid expensive complete replacements.

DSG Mechatronics Repair from Mosertronik

We repair your defective DQ381 (0GC) quickly and professionally. For the DQ200 (DSG7) we offer a repair kit for sale. As it is available for the DQ381 If there is no repair kit available, we will carry out the professional repair for you. If you have any questions, please call us or use our contact form.

DSG repair duration

As a rule, your DSG mechatronic is processed on the same day it arrives at our premises and leaves our premises the next day at the latest. For customers who require an even faster repair, we offer an express service by appointment. The repair then takes about 1-2 hours and you can wait on site for completion. Please make an appointment in advance by telephone.

More news entries

For further reading we recommend the article Instrument cluster repair or electronic repair.